Apollo AV-1 Parts

3D Models of the trigger and shaft for an Apollo AV-1 underwater scooter that can be 3D printed.

The Apollo AV-1 diver propulsion vehicle is a discontinued underwater scooter that is still widely used in the diving community. Even after Apollo discontinued the AV-1, divers continue to use this means of propulsion. There is one flaw in the scooter's design, however. The scooter's trigger assembly is poorly engineered and causes a range of issues; this includes getting the trigger stuck in the depressed position. As one can imagine, while 50 feet underwater, this is undesirable. A common fix for this issue is to drill a small hole on the top/front of the trigger. So, in the event of a sticky trigger, one can simply pull the string so that the scooter will turn back off. This is all fine and well until the dicontinued scooter gets old and finding the parts become more uncommon. A set of calipers, a 3D printer, and about a week more work than expected later, these parts are now available to print for anyone.

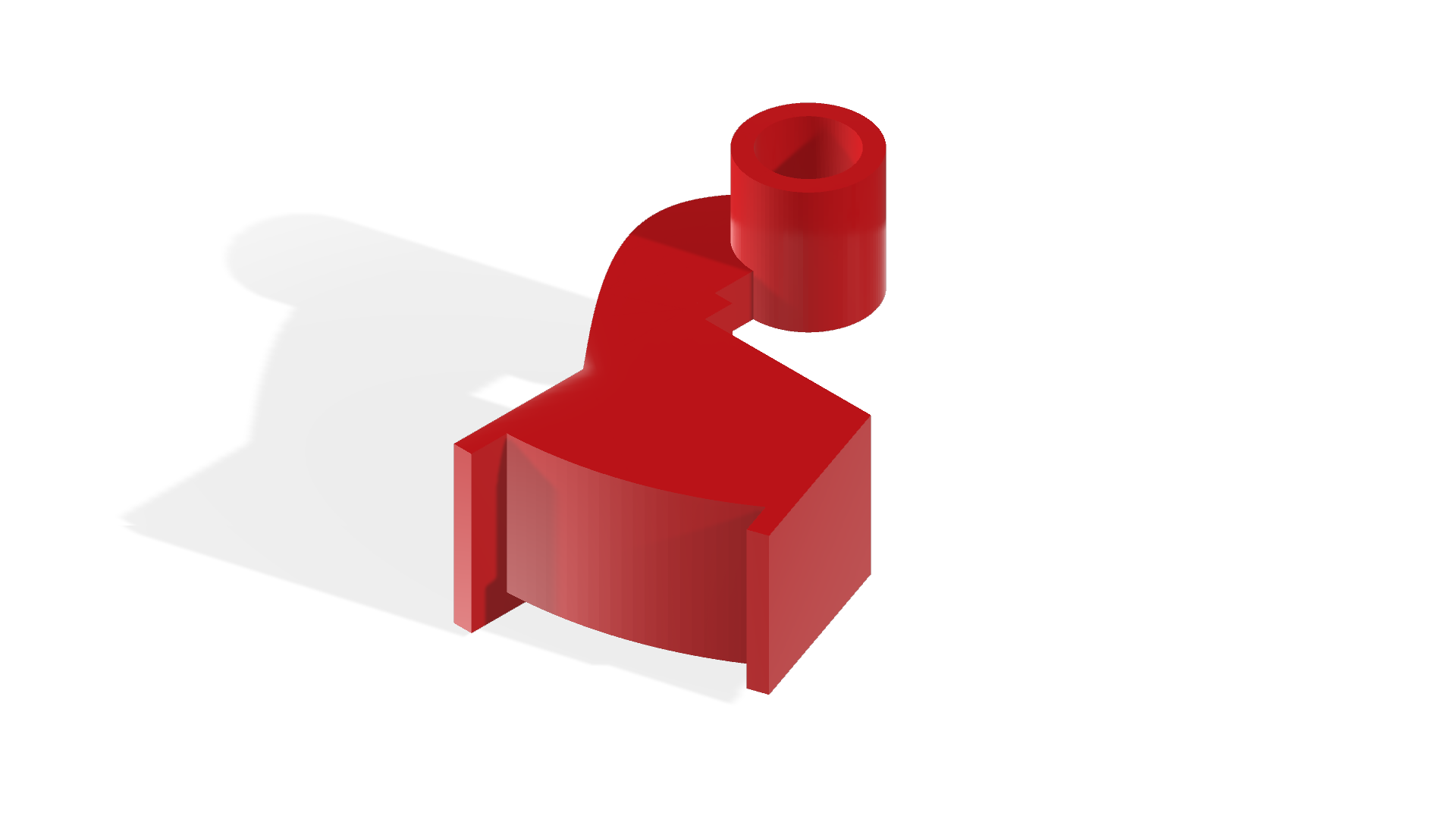

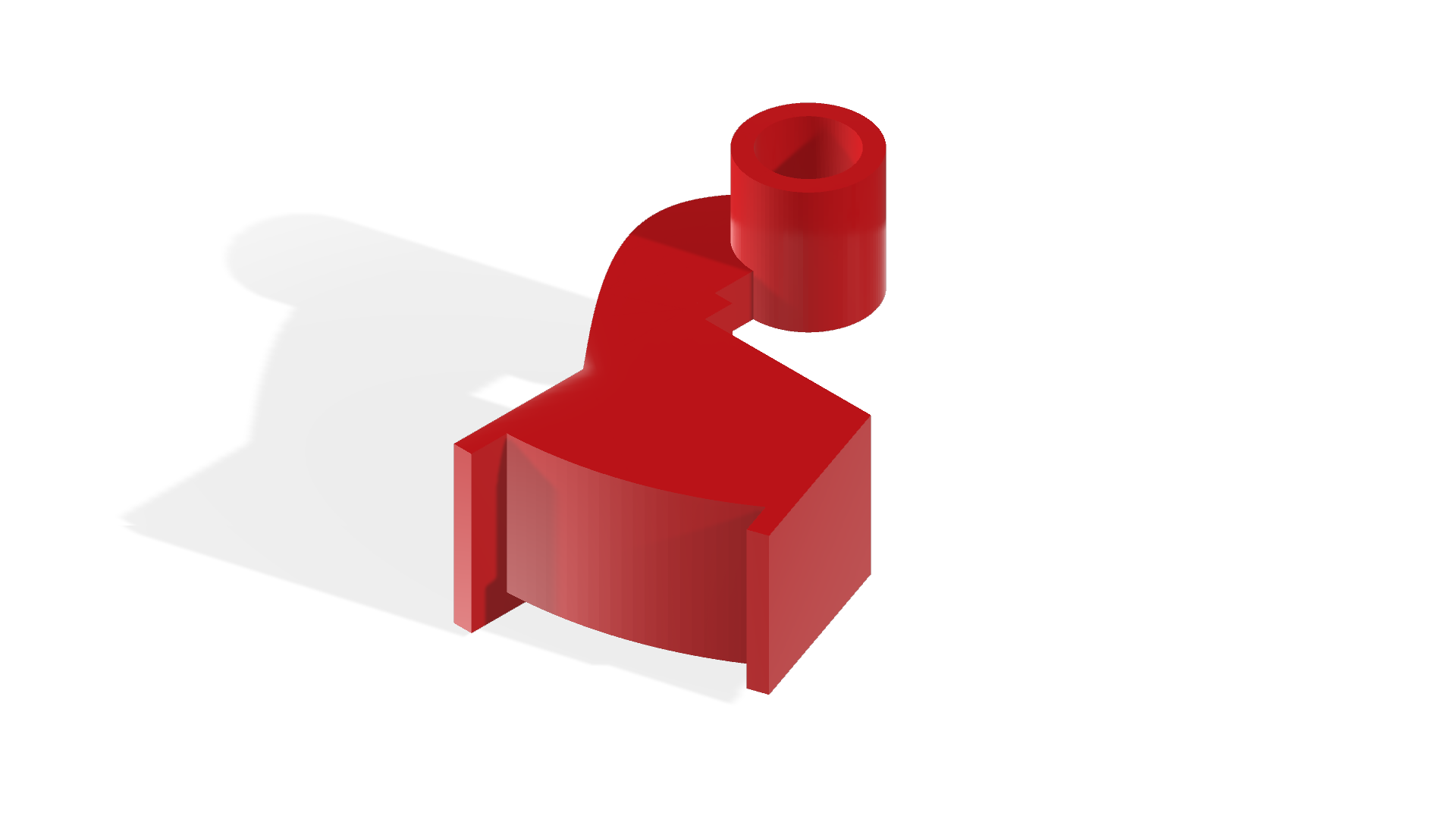

Trigger

This is the trigger part I designed in Fusion360. Anyone who comes across this page can take a shot at printing out a couple replacements. I took all the critical measurements of the part so that the best possible fit can be obtained, but I also took a few design liberties along the way. This included an added lip to the top of the trigger so that it can not longer be forced into the trigger body in the hope of preventing it from getting stuck in the first place. I have also reinforced the arm that connects the shaft to the actual trigger body due to the original trigger showing signs of plastic fatigue. I test printed these parts in both PLA and PETG, and both plastics seem to work well. There is no real convenient way to print this part, so I advise playing around with various orientations to see what works best with your specific print configuration. I predict resin printing would suit this part the best due to the intricate details, size, and durability requirements, but my FDM printer prints it adequately in the dozens of interations I have developed.

This is the trigger part I designed in Fusion360. Anyone who comes across this page can take a shot at printing out a couple replacements. I took all the critical measurements of the part so that the best possible fit can be obtained, but I also took a few design liberties along the way. This included an added lip to the top of the trigger so that it can not longer be forced into the trigger body in the hope of preventing it from getting stuck in the first place. I have also reinforced the arm that connects the shaft to the actual trigger body due to the original trigger showing signs of plastic fatigue. I test printed these parts in both PLA and PETG, and both plastics seem to work well. There is no real convenient way to print this part, so I advise playing around with various orientations to see what works best with your specific print configuration. I predict resin printing would suit this part the best due to the intricate details, size, and durability requirements, but my FDM printer prints it adequately in the dozens of interations I have developed.

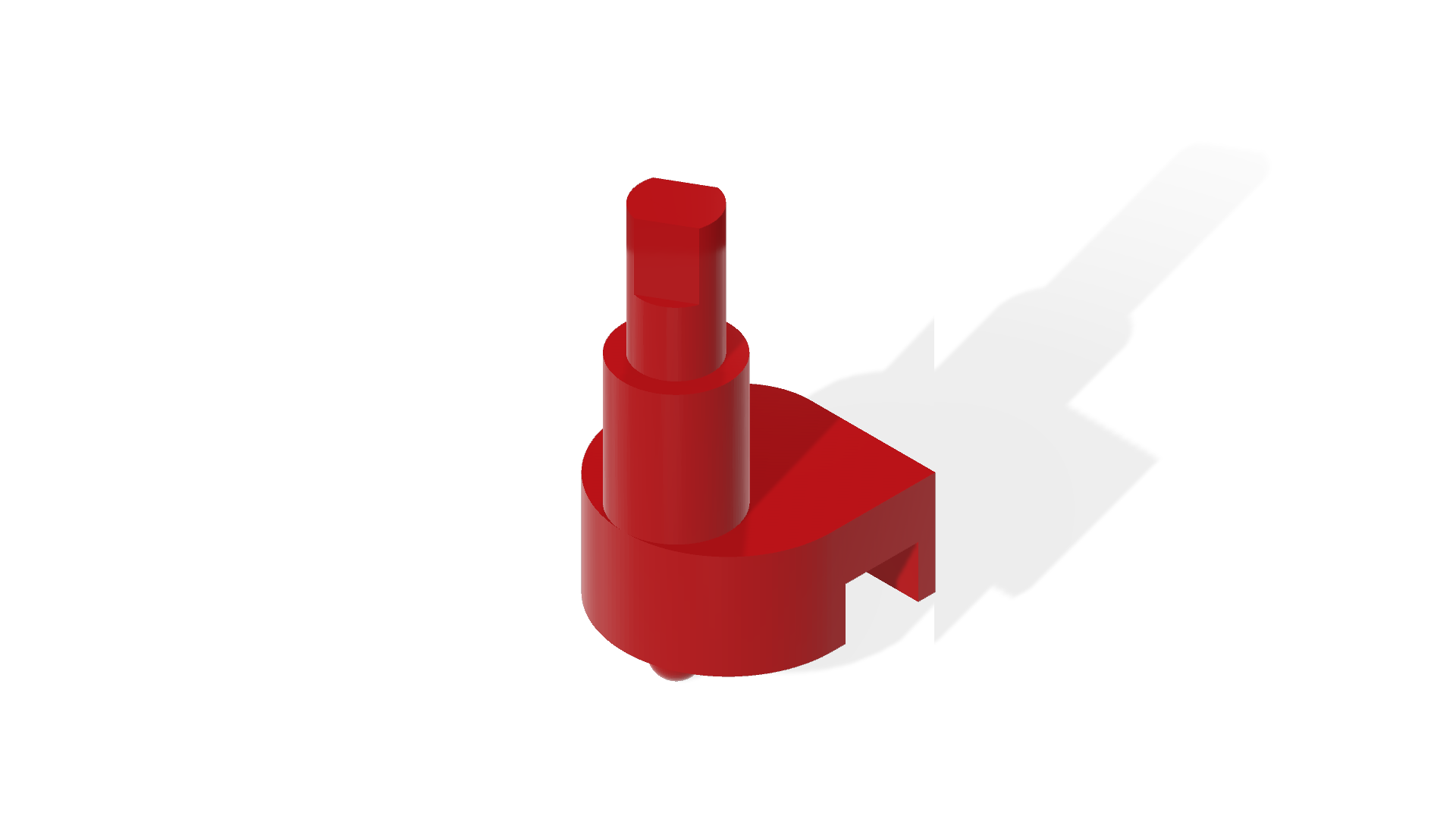

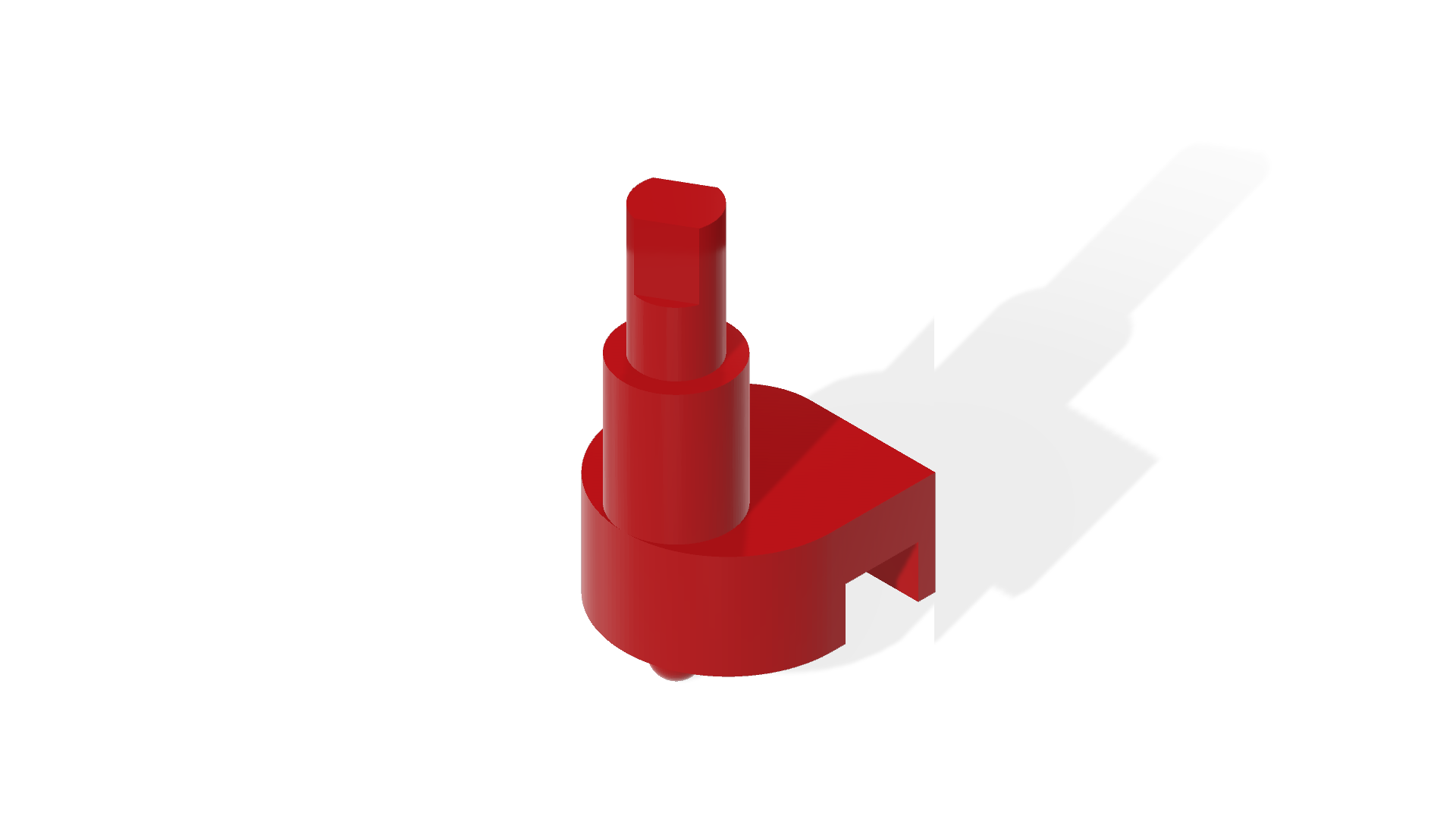

Shaft

This is the shaft part I designed in Fusion360. Much like the trigger part above, the precise measurements were adhered to strictly, while once again liberties were taken to aid in rigidity and ease of 3D printing. The location for the original reed switch magnet has been projected perfectly with respect to the shaft so that there is no misalignment through the full range of motion. The angle of the keyway that couples with the trigger part is also modeled perfectly for a snug fit. The bottom has been reinforced for 3D printing ease. Extra strength in this area can help provide a solid wide base to 3d print a vertical shaft on.

This is the shaft part I designed in Fusion360. Much like the trigger part above, the precise measurements were adhered to strictly, while once again liberties were taken to aid in rigidity and ease of 3D printing. The location for the original reed switch magnet has been projected perfectly with respect to the shaft so that there is no misalignment through the full range of motion. The angle of the keyway that couples with the trigger part is also modeled perfectly for a snug fit. The bottom has been reinforced for 3D printing ease. Extra strength in this area can help provide a solid wide base to 3d print a vertical shaft on.